- 20 20 CABINET DESIGN SOFTWARE COMPATIBLE SYSTEMS MANUAL

- 20 20 CABINET DESIGN SOFTWARE COMPATIBLE SYSTEMS FULL

- 20 20 CABINET DESIGN SOFTWARE COMPATIBLE SYSTEMS FREE

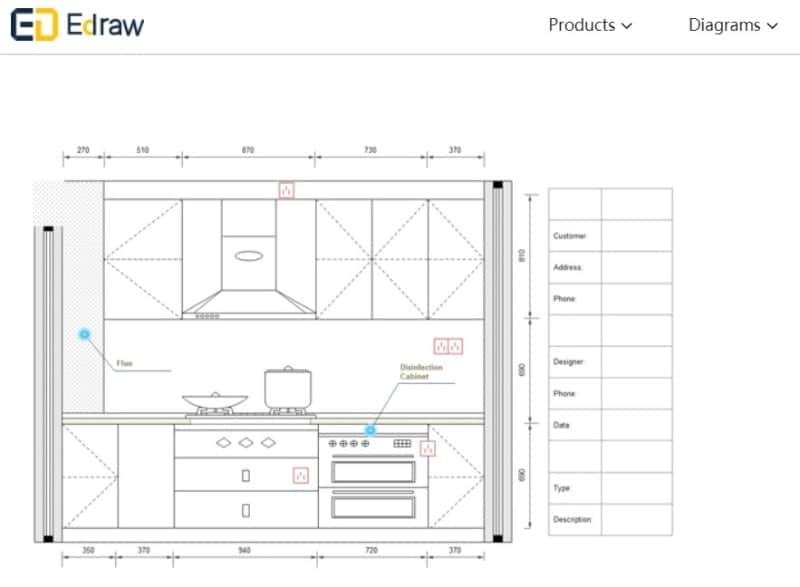

Technology has introduced numerous software that can design your kitchen in the shortest amount of time with accurate measurements, three dimensional design and plans and a 360 degrees panoramic view.

20 20 CABINET DESIGN SOFTWARE COMPATIBLE SYSTEMS MANUAL

Gone are the days when designing kitchen cabinets have been a hassle with heap of manual work such as jotting down notes, measurements and pricing list, running to a architect, draftsman or designer to draw it, ultimately with too many trials and errors.

20 20 CABINET DESIGN SOFTWARE COMPATIBLE SYSTEMS FREE

These programs are both free and paid kitchen remodel programs that can be used without a lot of time or money. The +Point to Point addition includes either DXF Output to 3rd party CAM applications or the ability to communicate directly with a CNC Machine using Screen to Machine™, technology from Hexagon's Manufacturing Intelligence division.Here we explore the top 17 kitchen cabinet design software tools to remodel or redesign your space. The capability to export to and synchronise materials with material handling systems. The +Drill & Dowel addition gives you the capability to export information to drill and dowel machines. With the +Chop Saw addition it is simple to export data to automated fence systems for chop saws. This provides the ability to export DXF and other popular formats common to CAM applications for further processing by a third-party CAM solution.

Interoperability is further strengthened with the +3rd Party CAM addition. The +3rd Party CAD Import addition makes it possible to import cut lists from third party CAD software and layered DXF files to define CNC machining. By simulating prior to machining, it can reduce errors and scrapped parts, saving time, materials, and money. +Simulation enables you to preview machine operations graphically on screen to ensure that parts will be machined properly. These labels are then converted to image files which can be printed in real-time using the CNC router's and/or the saw's built-in labeling system. Therefore the +Label addition also allows you to design part labels inside xMachining, using all available information, including an image of the part. Many newer generation CNC routers and NC saws include their own on-board real-time labeling solutions. +Label works in conjunction with xMachining to add bar-codes to each part that requires secondary machining (for example, with a point-to-point or CNC drill and dowel machine), enabling an easy flow from one process to the next.

In addition, the screen is updated automatically to show exactly which parts and panels have been completed.įull label design capabilities gives complete control over the data printed on the label. You can easily select parts by simply touching the screen and print easy-to-read graphic labels for each part. Ideal for nested-based manufacturing as well as traditional manual and NC panel saws, the +Label addition enables saw and CNC operators to clearly visualise the panel as labels are printed on-demand and placed on parts. Automatic tooling and toolpath generation.Integrated reporting (including basic part labels).Output to multiple NC and CNC machines simultaneously.

And if you use multiple types of CNC machinery you can rely on xMachining to automate workflows and send the right part, to the right machine, at the right time. xMachining has the capability to intelligently programme machinery by analysing part geometry and automatically creating toolpaths, choosing the right tool, and selecting the speed and feed rates.

20 20 CABINET DESIGN SOFTWARE COMPATIBLE SYSTEMS FULL

Operating with a full range of machines, including CNC routers, drill and dowel, chop saws, panel saws, haunching machines and edgebanders. XMachining is the most flexible, powerful and automated CNC software in the woodworking market. XMachining By automatically producing machine ready G-Code for a wide variety of CNC machinery, xMachining takes designs straight from Screen to Machine™

0 kommentar(er)

0 kommentar(er)